Stainless steel is one of the most versatile materials in modern engineering and manufacturing. Its unique properties make it indispensable in a wide range of applications, from kitchen appliances to industrial machinery. However, not all stainless steels are created equal. There are various types, each with its own distinct characteristics and applications. In this article, we will explore five common types of stainless steel and their respective properties.

Austenitic stainless-steel stands tall as a cornerstone material in various industries, thanks to its unparalleled corrosion resistance, durability, and versatility. In this comprehensive guide, we delve into the depths of austenitic stainless steel, uncovering its properties, applications, and why it's a game-changer across multiple sectors.

Explore the realm of ferritic stainless steel, a robust alloy prized for its corrosion resistance, magnetic properties, and affordability. Discover the key characteristics, commercial grades, and versatile applications that make ferritic stainless steel a cornerstone material in diverse industries.

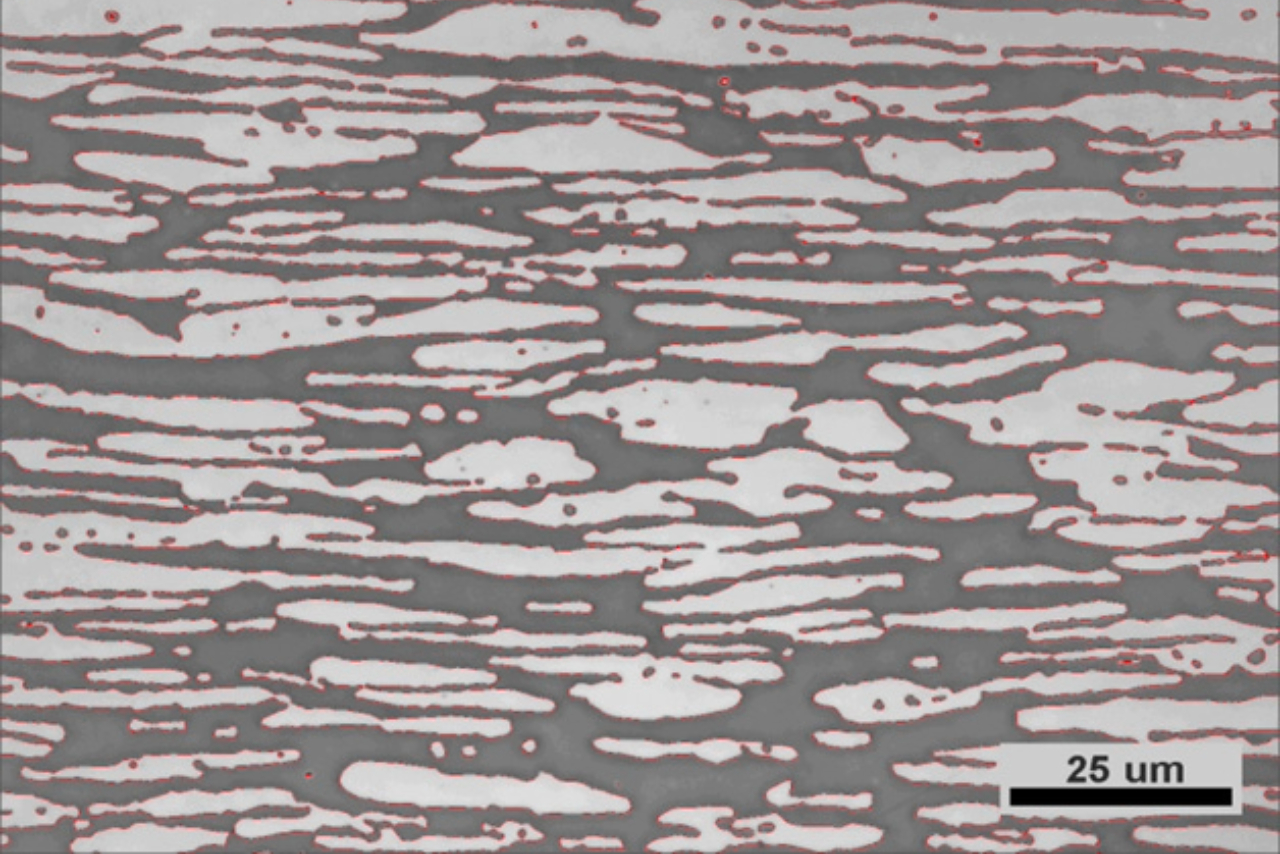

Delve into the world of duplex stainless steel, a remarkable alloy renowned for its combination of high strength, corrosion resistance, and cost-effectiveness. Discover the key features, commercial grades, and diverse applications that make duplex stainless steel a preferred choice in various industries.

Explore the robust qualities of martensitic stainless steel, a resilient alloy valued for its hardness, strength, and corrosion resistance. Discover the key attributes, commercial grades, and versatile applications that make martensitic stainless steel indispensable in various industries.

Discover the exceptional qualities of Precipitation Hardened Stainless Steel, celebrated for its unmatched strength, resilience, and corrosion resistance. Explore its key features, commercial variants, and pioneering applications across diverse industries.

Engineered plastics offer advanced materials tailored for high-performance applications across industries like aerospace, automotive, and medical. These materials provide exceptional strength, durability, and versatility, handling extreme conditions like high stress, temperatures, and chemical exposure. With superior wear, impact, and chemical resistance, engineered plastics are ideal for complex components. They are lightweight, cost-effective, and customizable, enabling precise manufacturing and enhancing design innovation in diverse sectors.