Precision machining stands as a cornerstone of modern manufacturing, embodying the art of sculpting raw materials into intricate components with unmatched accuracy and finesse. From oil & gas, aerospace, mining, and automotive industries to medical and electronics sectors, precision machined parts play a vital role in powering innovation and driving progress across diverse sectors.

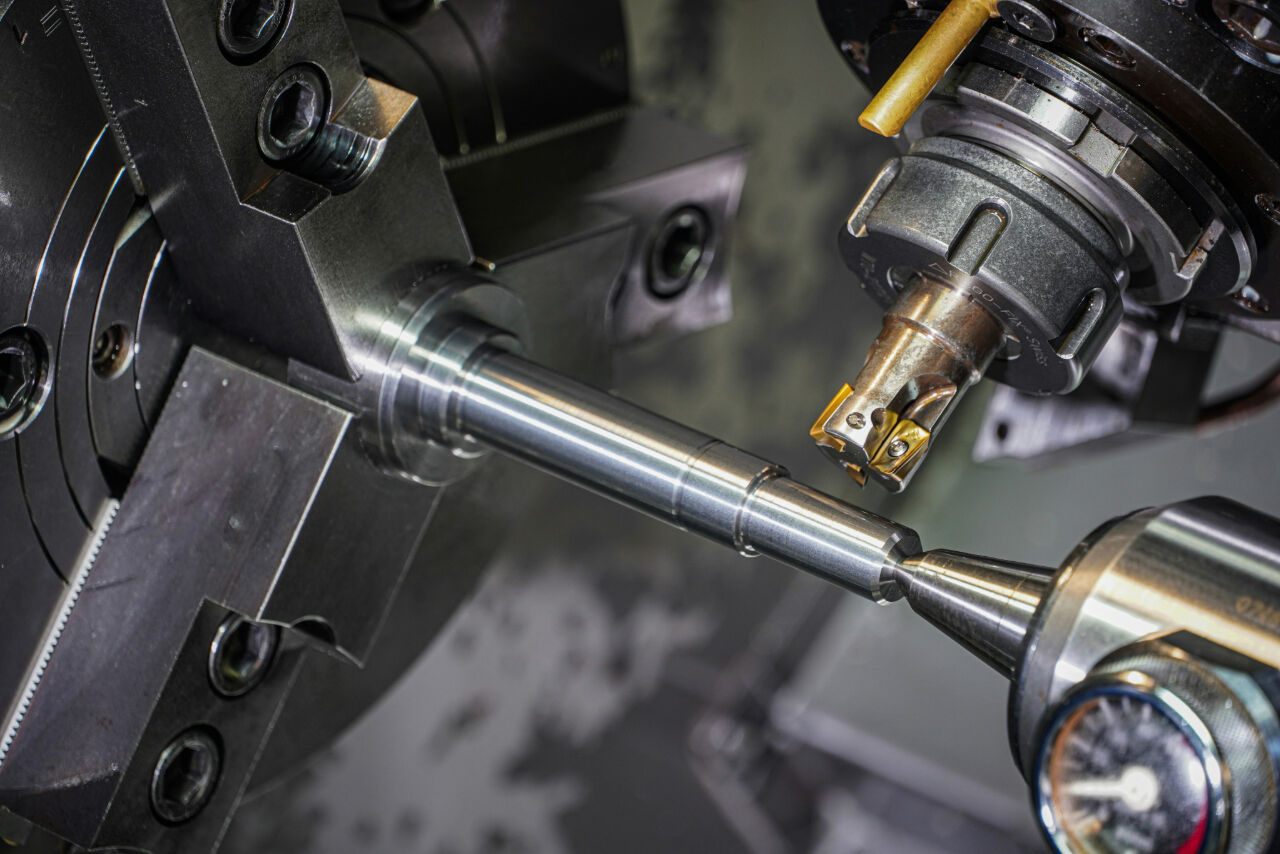

At its essence, precision machining involves the use of advanced machinery and cutting-edge techniques to shape raw materials into precise, complex geometries. Whether it's milling, turning, grinding, or drilling, each machining operation demands meticulous attention to detail and a deep understanding of material properties to achieve optimal results.

One of the key advantages of precision machining lies in its ability to deliver unparalleled accuracy and consistency. Advanced CNC (Computer Numerical Control) systems enable precise control over cutting parameters such as speed, feed rate, and tool path, ensuring uniformity and repeatability in every part produced. This precision is critical for industries where tight tolerances and exacting specifications are non-negotiable, such as aerospace and medical device manufacturing.

Moreover, precision machining offers exceptional versatility, accommodating a wide range of materials including metals, plastics, composites, and ceramics. Whether it's aluminum for lightweight aircraft components, stainless steel for surgical instruments, or titanium for high-performance automotive parts, precision machining can handle the most demanding materials with ease, opening doors to endless possibilities for design innovation.

Another notable advantage of precision machining is its efficiency and cost-effectiveness. By optimizing tool paths and maximizing material utilization, precision machining minimizes waste and reduces production time, resulting in significant cost savings compared to traditional manufacturing methods. Additionally, the ability to integrate multiple machining operations into a single setup further enhances efficiency, streamlining workflows and accelerating time-to-market for new products.

Furthermore, precision machining enables the creation of complex geometries and intricate features that would be impractical or impossible to achieve through other manufacturing processes. This includes tight tolerances, sharp corners, and intricate surface finishes, allowing designers and engineers to push the boundaries of what's possible in product design and functionality.

In conclusion, precision machining stands as a testament to the marriage of art and science in modern manufacturing. Its ability to deliver unparalleled accuracy, versatility, and efficiency has revolutionized industries worldwide, empowering innovation and driving progress at every turn. As we continue to push the boundaries of what's possible, precision machining remains at the forefront, shaping the products and technologies that define our future.

Our Capabilities

We specialize in providing high-quality precision machining services and precision machined parts tailored to meet the unique needs of our customers. Our machine shops are fully equipped to deliver: