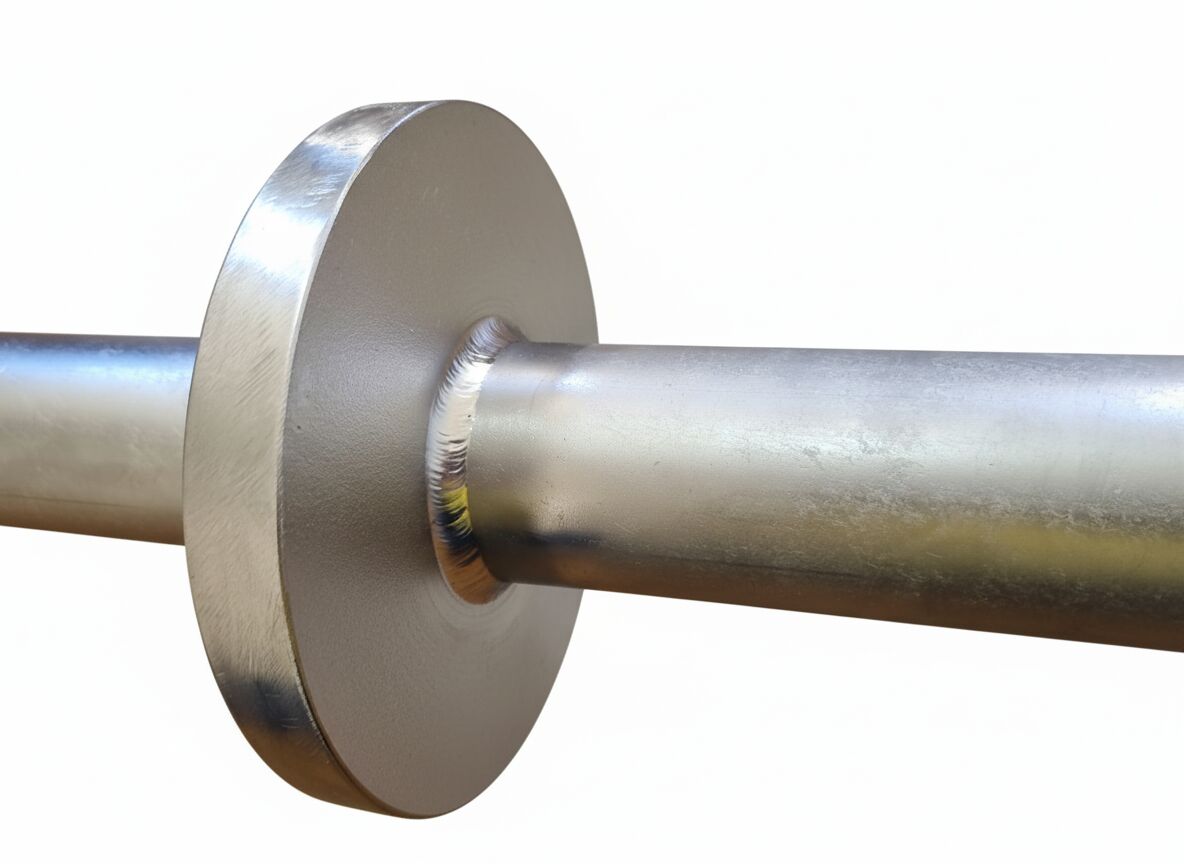

A leading EPC contractor faced a major schedule setback when four super duplex stainless steel puddle pipes (2” × 1 m) were missed from the original procurement package. These components were vital to completing civil works and allowing subsequent trades to proceed.

Local suppliers quoted lead times exceeding four weeks, threatening project deadlines and budgets. BEP Flow Solutions stepped in to deliver a fast, compliant, and cost-effective solution.

Scope of Work:

Outcome:

BEP Flow’s ability to combine precision fabrication, certified materials, and efficient project coordination ensured the client received a reliable, compliant, and cost-effective solution under tight time pressure.