We reverse-engineered a Spear Lance assembly using specialized acetal plastic, ensuring precise dimension and quality control. Our solution featured like for like replacement with non-standard thread compatibility and superior quality, meeting all customer requirements for seamless integration and enhanced performance in critical water filtration applications.

We successfully delivered plugs in super duplex stainless steel for a marine application, overcoming sourcing challenges with quick turnaround and competitive pricing. Our solution ensured high performance and customer satisfaction, reinforcing our commitment to quality and reliability in specialized projects.

When severe flange corrosion threatened to delay a client’s shutdown schedule, BEP Flow Solutions engineered a custom in-situ machining solution that overcame restricted access and tight timelines - restoring sealing integrity without extending downtime.

BEP Flow Solutions manufactured a simple yet brilliant spacer solution that spots hidden valve leaks before they cause actuator failures. Quick to install, cost-effective, and reliable—helping our customer to detect leaks and prevent actuator failures without stem replacements.

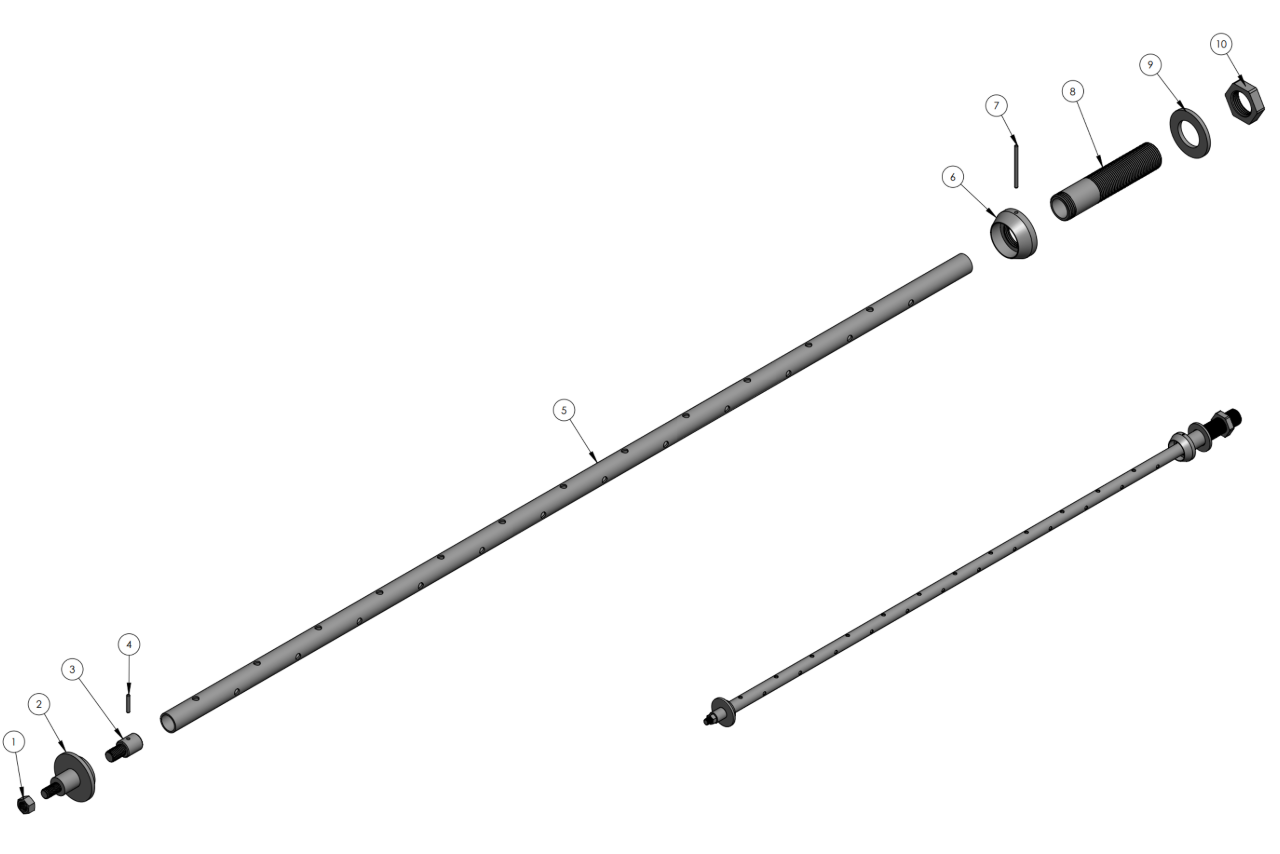

Fast-track fabrication of super duplex stainless steel puddle pipes for a construction EPC project. Delivered fully certified assemblies in just two weeks, enabling the client to resume critical civil works without delay while achieving significant cost savings compared to market alternatives.

Manufacture and supply of special-purpose super duplex stainless steel fasteners for a critical liquid ring vacuum pump overhaul in a nickel refinery. Delivered certified, precision-machined parts within two weeks - providing major cost and lead-time savings.