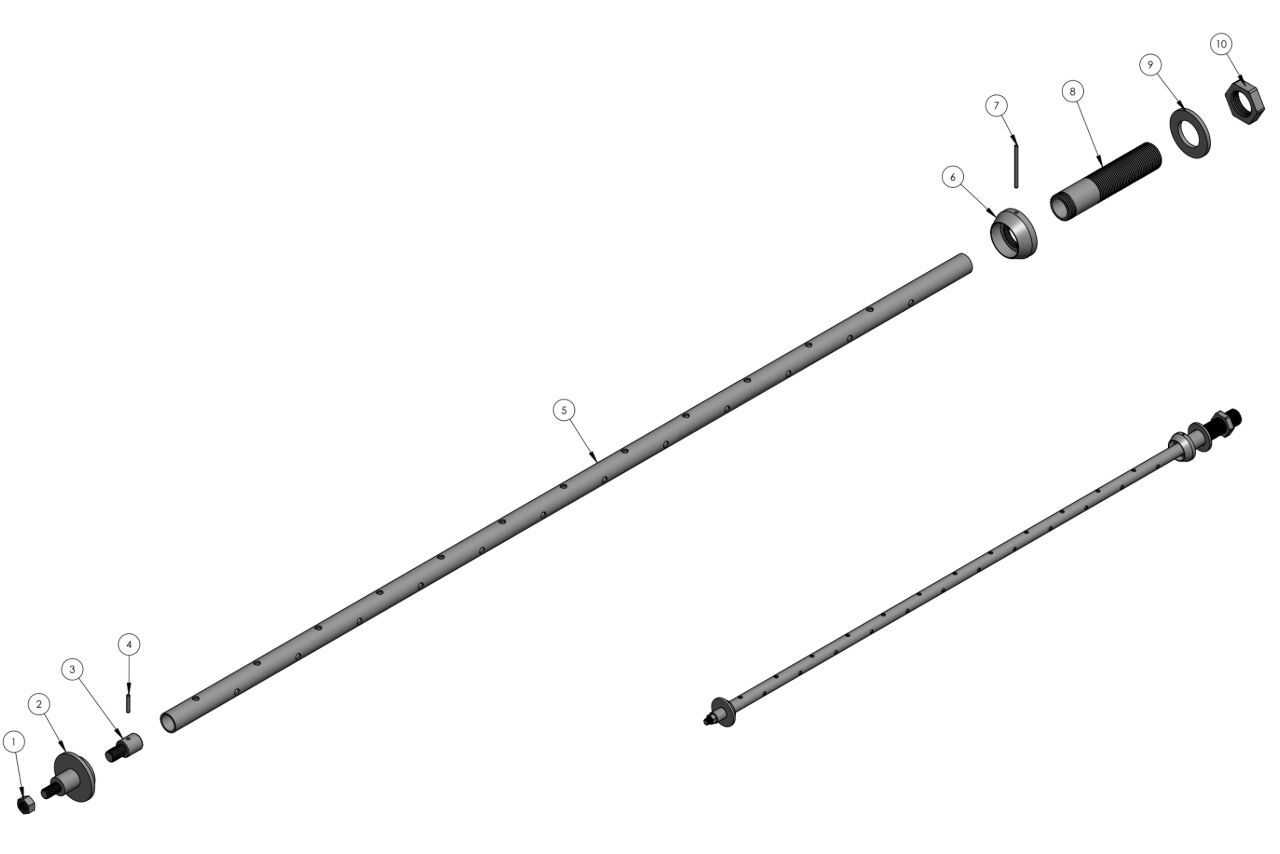

Project Overview:

A reputed Perth based company approached us to reverse engineer a Spear Lance assembly critical to their water filtration system. This assembly, comprising 10 components manufactured from a specialized black acetal plastic, required precision engineering to maintain performance in a high-demand operational environment. One of the most significant challenges was ensuring dimension control to achieve uniform water flow and equal pressure distribution throughout the system. Additionally, the design involved non-standard threads for seamless integration with existing components on site.

Key Components of the Assembly:

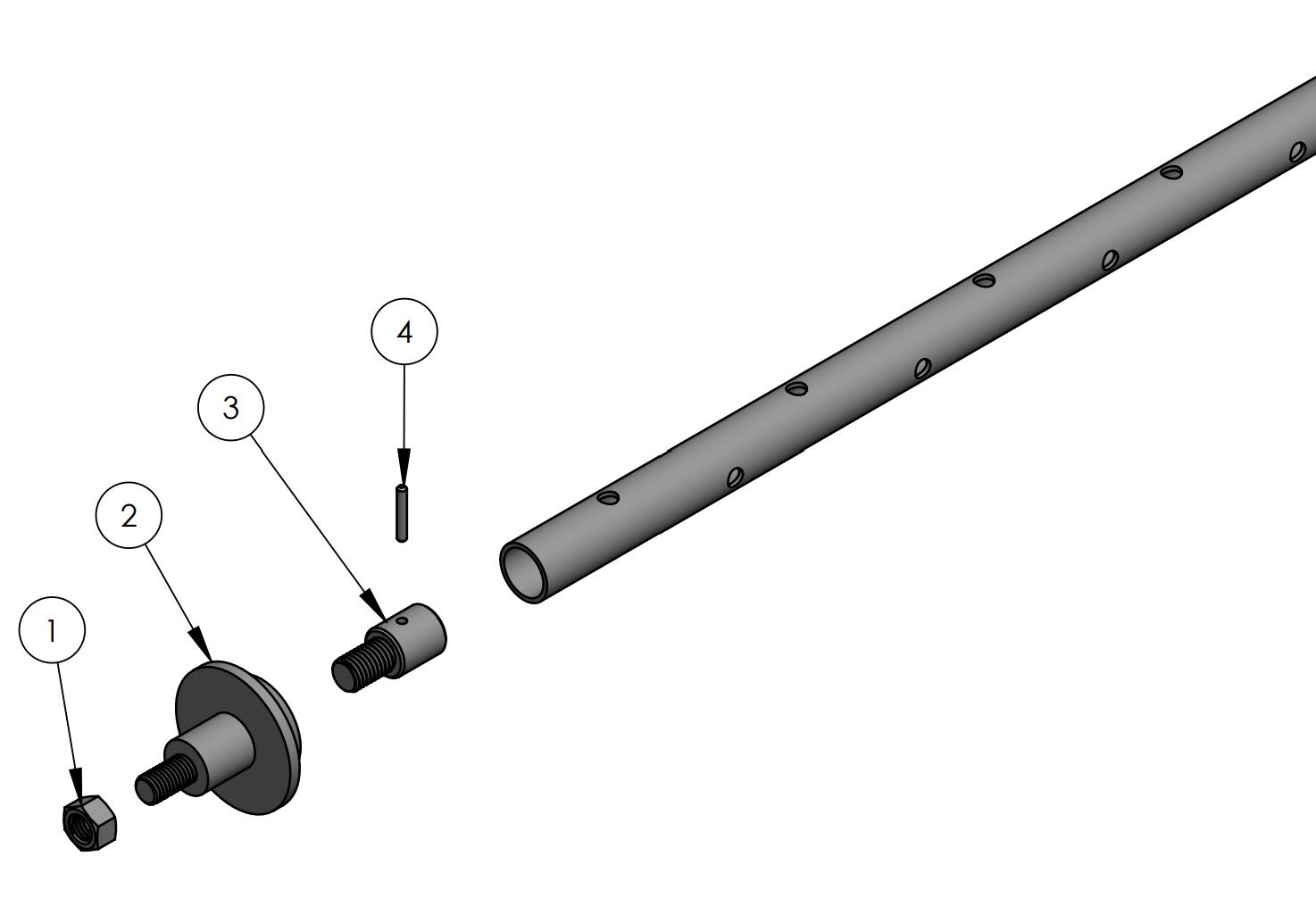

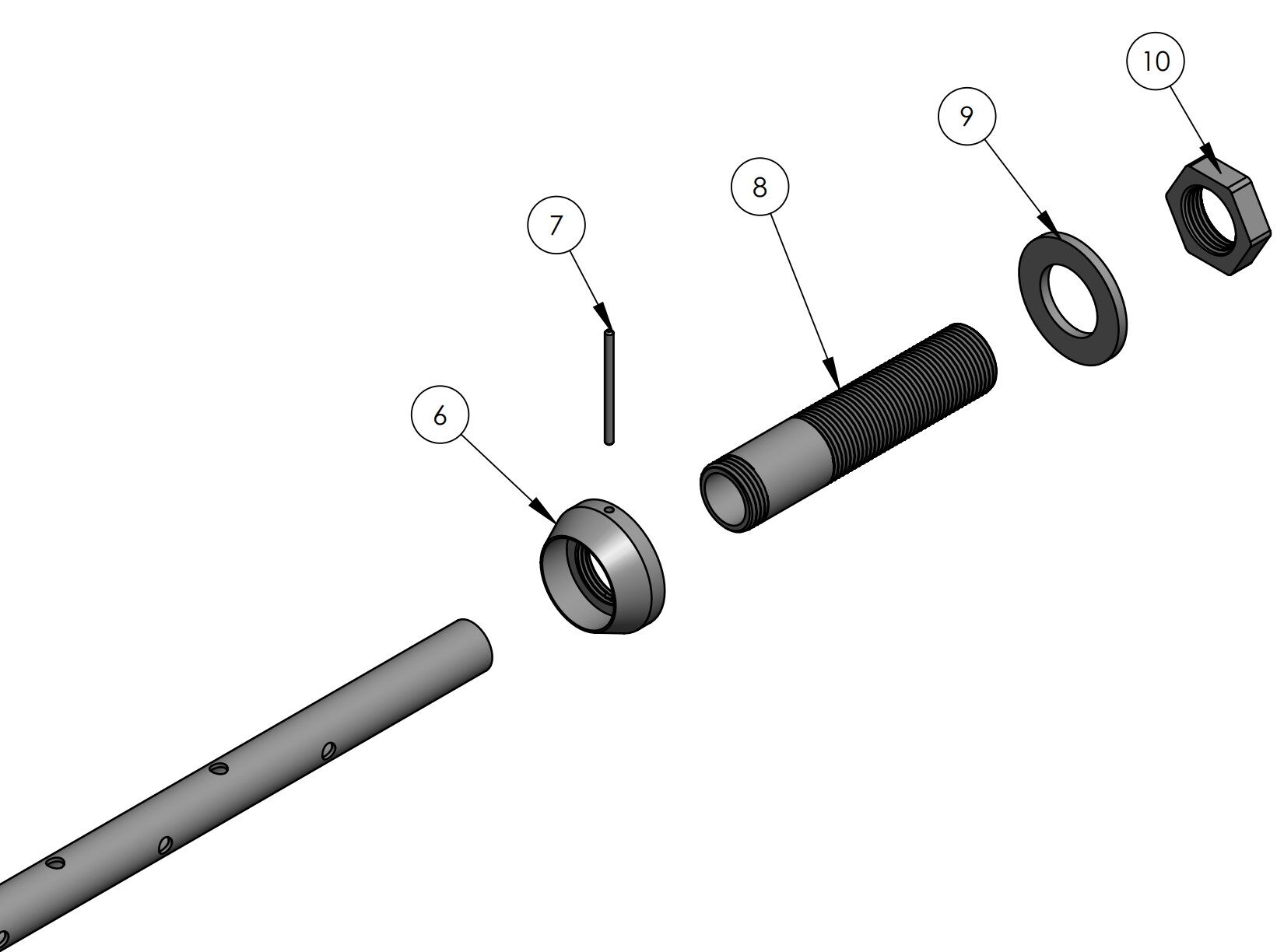

- Nuts (Parts 1, 10): Precision-crafted nuts featuring non-standard threads to ensure robust and secure assembly.

- Short & Long Fittings (Parts 2, 6): Custom-fabricated fittings designed for efficient connection with filtration pipes, adhering to tight tolerances for reliable performance.

- Short & Long Fitting Pins (Parts 3, 8): Engineered for secure alignment and stability within the assembly structure.

- Short & Long Pins (Parts 4, 7): Essential for maintaining component positioning and reinforcement under operational pressures.

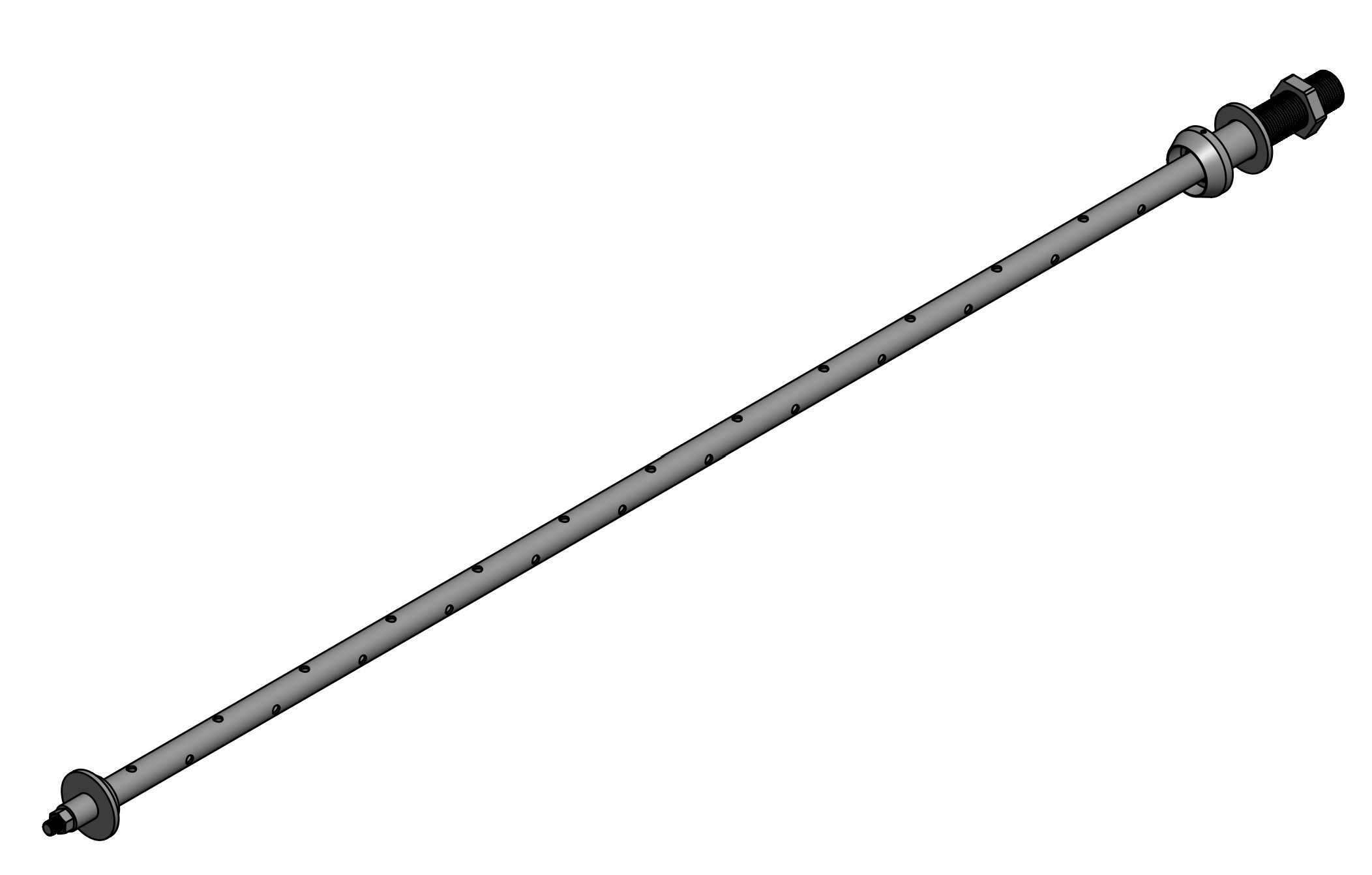

- Tube (Part 5): The core of the assembly, featuring precision-machined holes to ensure consistent water flow and balanced pressure distribution—a critical factor for efficient filtration and overall system performance.

- Washer (Part 9): Serves as a stabilizing element, enhancing assembly durability and operational reliability.

Our Approach:

- Collaborative Requirement Understanding: We worked closely with the client to understand the critical importance of uniform water distribution and component compatibility.

- Advanced Reverse Engineering: Comprehensive measurements and modeling techniques enabled us to recreate the entire assembly while ensuring accurate dimensions.

- Customized Thread Solutions: Non-standard thread requirements were met by developing custom tooling to guarantee seamless interchangeability with existing parts.

- Quality Control & Inspections: Rigorous inspection during manufacturing ensured dimensional accuracy, better quality control, and consistent performance.

Outcome:

Our reverse-engineered Spear Lance assembly exceeded the customer’s expectations by delivering superior quality, precise fit, and enhanced filtration performance. The final product ensured uniform water flow and equal pressure distribution, essential for the efficiency and reliability of the water filtration system.

Key Highlights:

- Customer-Focused Solutions: Comprehensive collaboration to meet specialized needs.

- Expertise in Precision Engineering: High accuracy maintained for hole placement to optimize water flow and pressure.

- Advanced Material Handling: Acetal plastic components expertly machined for strength and stability.

- Quality Assurance: Robust inspections ensured all components met stringent operational requirements.

This project exemplifies our ability to tackle complex engineering challenges and deliver solutions that ensure superior performance and customer satisfaction in critical applications.