Investment casting, or lost-wax casting, crafts intricate metal parts by creating a wax pattern, coating it in ceramic, and then melting away the wax to leave a mold. Molten metal is poured into the cavity, producing precise parts with fine details and smooth finishes. This method, despite being costlier and time-intensive, is preferred for its ability to create complex shapes and thin walls, making it invaluable in aerospace, automotive, and jewelry industries.

Sand casting, a versatile metal casting process, involves forming a mold using compacted sand around a pattern. Molten metal is then poured into the mold, solidifying to create the desired part. Widely used for its cost-effectiveness and ability to produce complex shapes, it serves diverse industries from automotive to defense.

Injection molding is a manufacturing process where molten material, typically plastic, is injected into a mold cavity under high pressure. Once cooled and solidified, the molded part is ejected. Renowned for its efficiency, precision, and ability to produce intricate shapes, it finds applications in various industries, including automotive and electronics.

Forging is a manufacturing process that involves shaping metal using localized compressive forces. This is achieved by hammering, pressing, or rolling the metal into the desired shape. It's known for producing strong, durable parts with excellent mechanical properties, making it ideal for critical components in industries such as automotive, aerospace, and construction.

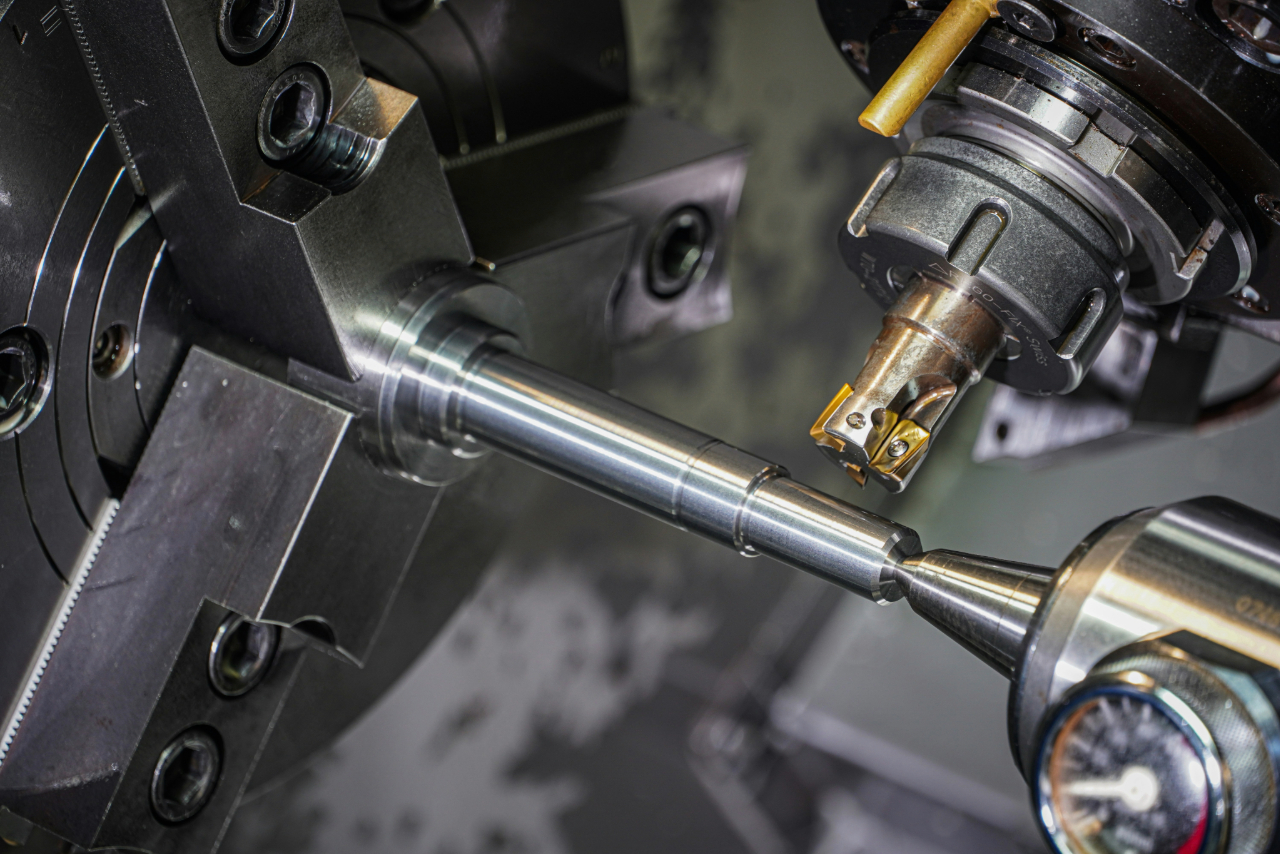

Precision machining is a manufacturing process that involves removing material from a workpiece to create a precise and intricate final product. This is achieved using specialized machines such as CNC (Computer Numerical Control) mills and lathes, which operate with high accuracy and repeatability. Precision machining is essential for creating components with tight tolerances and complex geometries, commonly used across industries.

At BEP Flow Solutions, we specialize in 3D scanning and reverse engineering to recreate obsolete parts with precision. Our approach bridges the gap when parts are no longer available, offering cost-effective, accurate replacements. With decades of industry experience, we don’t just replicate parts; we apply engineering principles to ensure optimal performance, solve existing problems, and incorporate strategic upgrades. We ask the right questions to deliver the perfect solution, ensuring minimal downtime and maximum efficiency.

We specialise in workshop fabrication of piping spools, structural steel, skids, platforms, pressure and non-pressure equipment. Our proven welding and fabrication processes ensure precise, reliable, and cost-effective solutions tailored for mining, industrial, and infrastructure projects. We focus on delivering quality workmanship with strict adherence to applicable standards, helping you meet project timelines without compromising safety or performance. Our experienced team works closely with clients to provide flexible and efficient fabrication services that support both new builds and maintenance requirements.